Servicing Sydney Metro, Western Sydney & Southern Highlands

Follow us on social media:

Servicing Sydney Metro, Western Sydney & Southern Highlands

Joinery refers to the professional craft of combining different materials, usually wood, metal, or a combination of the two, for the purpose of achieving structures that are both functional and beautiful. The process of joinery involves various accurate cutting, shaping, and assembly techniques with the aspect of strength and durability. Unlike in conventional construction methods, engineering joinery would require an extra appreciation of the behavior of materials under stress, load, and other environmental stressors. MGB Joinery and Building has over 10 years of experience in perfecting these techniques to ensure that craftsmanship would be the best for every project.

Joinery is now indispensable in modern engineering practices on residential or commercial properties. From luxury apartment interiors to office fit-outs, joinery techniques lead to achieving aesthetic allure and structural soundness. Precision joinery leaves no space for defecting materials like wood or metal and thus improves the stability of the whole building structure. MGB Joinery looks for ways to achieve accuracy and quality in their joinery methods in order to deliver a finished product that exceeds client expectations. Whether it is wood joinery for fine cabinetry or metal joinery for structural frameworks, attention to detail distinguishes us.

While often confused with carpentry, in engineering terms, joinery is a distinct craft. Onsite construction is common in the latter. The word ‘carpentry‘ essentially refers to the construction of broader elements like framing and structural support. On the other hand, joinery is mostly done in workshops where there is pre-cutting of material, cutting to shape, and preparation for installation with higher accuracy. Joinery is all about providing components which fit right on-site with no need for on-site modifications. At MGB Joinery, we do joinery and carpentry ensuring that every element of your project leaves our premises completed at the highest standard—from design to final installation.

Mastering your projects using deep knowledge of techniques and methods for joinery materials by MGB Joinery and Building would assure you of having the best results, from delivering quality to clients and corporate offices to the richest residential spaces.

Joinery plays a very crucial role in the successful execution of large-scale engineering projects. It may be a high-rise fit-out office, a luxury apartment development, or any other development that requires large-scale engineering support. The precision and strength of joinery techniques will ensure structural integrity while building a complex. Joinery engineering is known to provide strong connections in the material connection, which reduces the chances of structural failure over time. MGB Joinery and Building, an organization experienced for over ten years, holds the view that sturdy and dependable solutions are created through the finest joinery methods and each project stands the test of time.

Precision joinery is very important in the world of engineering in order to maintain structural integrity. Precise conjunction and stable gluing of materials, whether wooden or metal joinery, make sure that every detail matters to contribute to the overall stability of the project. At MGB Joinery and Building, precision in all aspects of the work undertaken is what defines us; our structural joinery skills ensure proper success in each joint without much emphasis on detail, though durability and aesthetic value are offered at the same time. From ornate wooden works to the accurately aligned steel, we bring craftsmanship along with the approach of an engineer towards engineering know-how to deliver superior results.

Engineering joinery can at times utilize a variety of materials depending on the requirements and specifications required by the project. The most basic ones are wood and metal, which are known for their robustness and versatility. Wood joinery is used widely both in residential and commercial places for bringing about warmth and an appeal that stands the test of time. Metal joinery is heavily preferred for the strength and durability aspect and is very common for most commercial or industrial projects. MGB Joinery and Building ensures that the materials used in joinery are all of high quality. It, therefore, means that every project given to us will always be done to last a lifetime. Our team efficiently chooses and manages these materials to suit specific needs required for different projects.

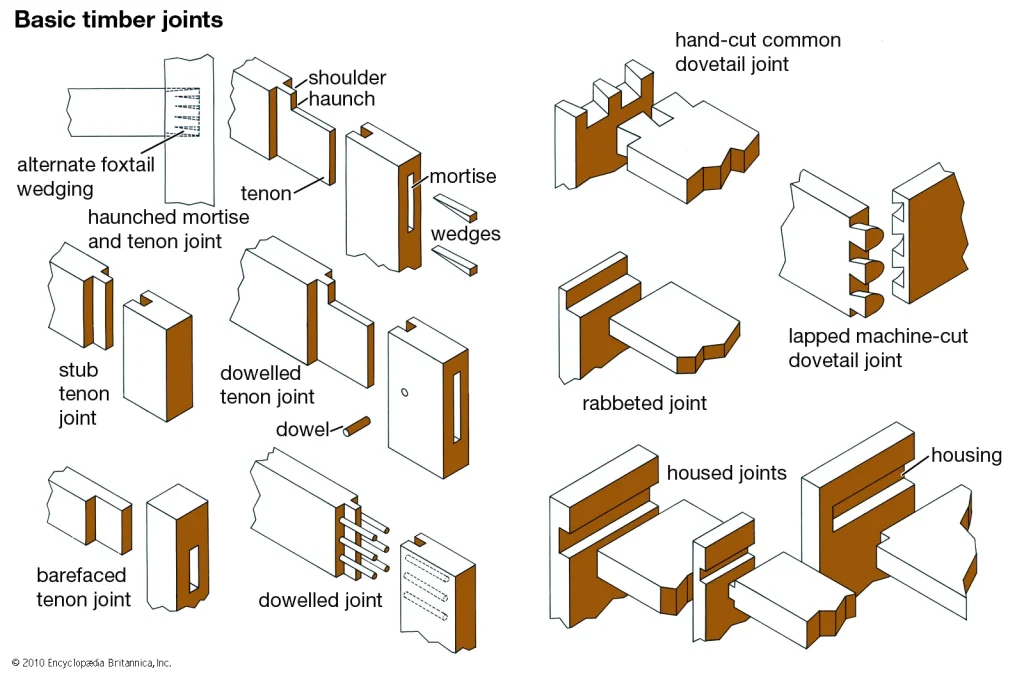

Joinery engineering has seen much development over the years with a perfect blend of traditional craftsmanship and modern innovation. The mortise and tenon or dovetail joints are some of the time-proven techniques, which depend entirely on the accuracy and precision of craftsmanship, and hence result in strong and stable structures. These have been in use for centuries as wood joinery and are widely integrated into residential and commercial projects. However, modern joinery techniques offer great flexibility and more durability for long projects since metals and novel systems of fixations were introduced. The art of bringing the classic craft together with the advanced engineering method of putting joinery together places MGB Joinery and Building on a different pedestal; there is always proper structural integrity and an overall aesthetic value attached to each work carried out.

The mortise and tenon joint is another common joinery technique applied in structural engineering that offers high strength and variety. It comprises a projection, the tenon, fitting perfectly into the cavity within an item, referred to as a mortise. Therefore, it is a safe and strong connection that does not require nails or adhesives. This is particularly common in wood joinery in the framework and structural components, where the accuracy involved in the joinery will be crucial in holding the structure intact. MGB Joinery and Building uses mortise and tenon joints in various projects, thus ensuring every connection is as strong and reliable as one could expect from this kind of application. It is ideal for the most complex residential and commercial applications.

Dovetail joinery is highly recognizable, with its interlocking shape that is both strong and aesthetically pleasing. The technique is very common in woodworking applications such as cabinetry because the joint looks beautiful and can offer long-term strength. Being stress-resistant makes dovetail joints particularly preferred in engineering projects because of excellent structural stability. We apply that precision joinery at MGB Joinery and Building in functional as well as decorative contexts to ensure each one is both performing well and adding to the overall craftsmanship of the project.

Joinery plays a vital role in civil engineering works, mainly in significant infrastructure projects. From bridges to public buildings, precision techniques of joinery help ensure structural strength and longevity. Wood joinery and metal joinery are often combined to create strong, long-lasting frameworks in civil engineering. The techniques of structural joinery, such as mortise and tenon, are most often used to attach beams and supports, thus creating tight connections that can stand up to a great deal of load stress and environmental impact. At MGB Joinery and Building, the engineering joinery is put into each project to ensure the highest quality in durability and precision.

Precision joinery is important in mechanical engineering for making components or structures that need to work perfectly under exacting conditions. Whether it is metal joinery for machine parts or the exclusive customized methods of joinery in fabrication, it remains accurate and perfect. Joinery techniques also minimize wear and tear, hence a smoothened mechanical system. My experience at MGB Joinery and Building makes it possible for me to give high-quality solutions that deliver well within the requirements of mechanical engineering projects. In mechanical engineering projects, the smallest joint can make a huge difference in the overall working of something.

Some of the most sophisticated joinery techniques are required in aerospace engineering, not so much because aircraft demand massive levels of strength, but because safety is tied directly to functionality. In this industry, assembly can involve joinery in airframes through to interior components. Metal joinery is a particularly crucial aspect of this industry, as the structures involved have to support very high stresses while having to be as light as possible. Innovative joinery materials and techniques are a vital part of the aerospace industry’s development of components that are strong yet efficient. At MGB Joinery and Building, we fundamentally believe in joinery, whether advanced or simple, as essential to aerospace as to any type of construction or renovation project. We apply the same close attention and precision to our work, no matter the scale.

Wood, metal, and composite materials are the most preferred materials to use in engineering joinery. The outcome is effective both functionally and aesthetically appealing. Each material, according to the requirements of the project, has an advantage compared to the next one. For example, wood joinery is chosen because of its warmth, flexibility, and the intricacy of the shaping it allows. Cabinetry and custom interiors for residential projects, precision joinery techniques—the dovetail or mortise and tenon joints—can be the difference between a breakable connection that may rupture and one that will remain tight, strong, and durable. Commercial and industrial applications are widely achieved through the application of metal joinery. This is because it has great strength and endures some environmental factors. What’s more, composite materials represent a combination of different elements that are perfect for engineering joinery: highly durable and resistant to wear and tear in the high-use environment. At MGB Joinery and Building, we provide a wide range of joinery materials for every project while striving for the best performance and durability.

Material selection directly impacts how structural integrity and durability are maintained at the completion of the final product, as it is related to the joinery in an engineering project. For example, wood joinery can vary from metal joinery since wood behaves so differently with changes in moisture and temperature. Joinery techniques for structural purposes that are applied for the wooden beams used in constructing a house must take into account expansion and contraction, whereas techniques must be incorporated in making metal joinery to ensure resistance from rust and corrosion. In addition, it will only join these materials safely, which helps in reducing any potential failure or weakness over time. At MGB Joinery and Building, we carefully consider the best joinery materials and methods for each project by utilizing our engineering expertise in joinery together with top-quality materials to create the best results. Whether it is intricate wood joinery for a luxurious apartment or heavy-duty metal joinery for a commercial office fit-out, the smallest detail is designed to flawlessness.

CAD introduced a revolution in the joinery world of engineering and marked a new dimension to the craft. CAD enables joiners to design and visualize complicated structures to the finest detail before ever cutting any material. Joinery techniques such as dovetail or mortise and tenon can be planned with exacting measurements by using CAD software, providing perfect alignment and a seamless fit. This means a lower chance for errors and mistakes that involve wasted materials, so it saves time and money in the long run. At MGB Joinery and Building, we employ the latest CAD technology to design the best joinery solutions made of wood and metal for high-end residential and commercial projects with precision joinery.

With technological advancement, robot-based methods have increasingly been included in joinery. A robotic joinery system can perform the most complex joinery tasks much more accurately and swiftly. This way, the machines produce cuts, drills, and assemblies very directly with minimal human error and efficiency. It is especially suitable for large-scale engineering projects where uniformity and efficiency count most. Plus, there is design innovation that provides the opportunity of achieving more complex shapes and joinery methods that are problematic or impractical for manual labor. At MGB Joinery and Building, we track emerging technologies, so we know in advance what is going on in the industry and can quickly apply the best solution to what our customers need.

With 3D printing, the engineering approach towards joinery is all set to change dramatically. It allows for the development of custom materials and custom components with extreme precision for joinery. Using composites of plastic, metals, or wood itself, intricate joinery elements can be produced for fitting perfectly into a larger structure. This method also leads to greater capabilities in designs that cannot be obtained using traditional joinery. As 3D printing technology continues to evolve, it should be an integral part of joinery engineering, and therefore new possibilities for the building of better and more efficient structures are likely. At MGB Joinery and Building, we like the prospects offered by 3D printing and its strong ability to enhance the durability and creativity of our joinery projects.

At MGB Joinery and Building, we keep in line with the advances in engineering joinery innovation by embracing modern technologies such as CAD software, robotics, and 3D printing. We combine all these advanced tools with traditional craftsmanship so that every project undertaken receives a sense of precision as well as artistry. It might be the structural joinery for a commercial office fit-out or bespoke wood joinery for a luxury apartment; our team always aims to deliver the best results.

The most common engineering joinery problem is the repair of weak points, which are material interfaces in structural joinery. Engineering joinery entails very accurate implementation. A small defect in the application of joinery principles can weaken the overall structure and make it ineffective. For instance, wood joinery might degrade with the progressing natural elements that affect them, such as humidity or temperature, while metal joinery is more likely to have problems relating to corrosion. At MGB Joinery and Building, we avoid weak points in our joinery by choosing the proper materials and techniques for every project. Whether this is applying the latest in precision jointing techniques or applying protective coatings to metallic joints, we minimize weak points to deliver lifetime durability.

Tolerances and stress points are another major challenge of engineering joinery. Tolerances refer to the allowed deviation from the exact dimensions, and even little deviations lead to stress concentration in joinery engineering. Therefore, precision joinery has become necessary in managing these stress points so that the connections become tight and secure, especially in areas with high-stress intensity, such as building structural joinery in huge commercial structures. At MGB Joinery and Building, sophisticated joinery techniques combined with tools such as CAD software ensure precise tolerances, ensuring that every joint is well aligned and able to support the stressors over time.

The science of engineering joinery continually evolves. Innovations keep being made to overcome common challenges. For example, using contemporary materials like engineered wood and composites, the resistance to environmental degradation is significantly higher than its natural counterpart as it does not warp nor weaken with age and exposure to weather. In addition, precision in intricate joinery methods has been hugely advanced through improvements in robotic joinery and 3D printing, eliminating human error and increasing structural integrity. We stay updated on the latest findings about joinery engineering and utilize them in our projects to deliver good results for our clients’ interests. Whether it’s using high-class materials or more sophisticated techniques, we are dedicated to overcoming the challenges that joinery poses to achieve excellent outcomes.

Currently, sustainability is becoming a major concern in the construction and engineering sectors, and joinery engineering plays a significant role in reducing environmental damage. Joinery material selection directly impacts the sustainability of a project. For example, sustainable wood joinery involves the use of timber from managed forests where replanting helps in minimizing deforestation. Also, engineered wood products and recycled metals are being considerably used in modern joinery techniques while maintaining durability with the lowest possible environmental footprint. At MGB Joinery and Building, we focus on using eco-friendly materials, so our projects meet not only the existing quality and structural integrity standards but also the latest standards of sustainability. Whether it’s wooden joinery for a residential fit-out or metal joinery in a commercial build, our emphasis on sustainable practices impacts your project favorably as well as the environment.

One of the main positive aspects of modern joinery engineering is its ability to minimize material waste. Advanced machinery, such as CAD software and robotics, powers precision joinery techniques. Through these techniques, precise cutting and assembly of materials with minimal offcuts are made possible, virtually reducing waste material usage while maximizing resource use. At MGB Joinery and Building, we use precision joinery methods that save materials while delivering a quality product. We can keep costs low for clients by saving more through reducing waste; meanwhile, this approach enhances the sustainability of construction. Further, through our policy of minimizing waste, we ensure that all materials applied in a project are disposed of or recycled responsibly.

By choosing MGB Joinery and Building, you are not just selecting a practice that excels in craftsmanship and precision but one committed to sustainable practices. Our joinery engineering is assured by quality, innovation, and concern for the environment—values that ensure your project has the highest durability and sustainability in mind.

Finding the right joinery methods for your project involves balancing aesthetics and functionality with regard to the structure. The material you’re working with, whether it’s wood joinery or metal joinery, will make all the difference in selecting the best joinery techniques. For instance, wood joinery may require the employment of ancient techniques such as dovetail or mortise and tenon joints, which are recognized for their strength and aesthetic value. On the other hand, metal joinery demands sophisticated fastening methods like welding for structural integrity. The scale and complexity of the project are also vital aspects. For commercial purposes, the structural joinery has to be accurate and strong, while residential projects may benefit from more ornate and detailed joinery methods. At MGB Joinery and Building, we assess each project individually to select the best type of joinery that will be both long-lasting and aesthetically pleasing.

Engineering joinery decisions always demand consultation with experts. Modern joinery engineering is complex, and large-scale projects require extensive knowledge of materials and techniques. MGB Joinery and Building brings over 10 years of experience in perfecting various types of joinery materials and precision joinery techniques. We collaborate closely with our clients to understand their project details and guide them through the joinery methods that best meet their structural and design goals. Whether it’s a luxurious apartment fit-out or metal joinery for office space, we offer expert advice and hands-on solutions to ensure that every joint is expertly crafted.

Combine your project with MGB Joinery and Building, and seize the advantage of experience gained over years of joinery engineering. Precision in joinery, combined with personalized solutions, ensures that each method matches your exact project requirements, providing the best quality of workmanship. From material selection to final installation, we are here to ensure that the techniques we use will stand the test of time.

Looking for precise and expertly crafted joinery solutions for your next project?

Reach out to MGB Joinery and Building for consultation with experts to find the best high-quality joinery solutions for your project.

1. How long does a joinery project typically take?

A joinery project has a duration that depends on the complexity, materials used, and scale of the work; cabinetry could be a day or two, while large-scale structural joinery in buildings may take weeks or months. MGB Joinery and Building completes very efficient joinery projects with fast turnaround time without compromising quality.

2. What are factors that determine the price of an engineering joinery project?

There are many factors that determine the cost of a joinery project. Such factors include the type of materials, for example, whether it is wood, metal, or even composites. Another factor is the complexity of the joinery techniques and the size of the project. In that regard, special designs can contribute to increased costs, also high-end materials and precision joinery methods-while ensuring that the end result is durable and aesthetically pleasing.

3. Can joinery be applied to both residential and commercial projects?

Yes. Joinery is versatile in such a way that it can be applied to both residential and commercial projects. It doesn’t matter whether one needs custom cabinetry in a home or would require a rather complex structural framework in a commercial establishment. The technique used will be one which addresses the needs of the project.

4. What is the difference between custom joinery and prefabricated components?

Custom joinery is crafted to the dimensions and specifications of a project in order to achieve exact fit and unique details about a design. Of course, pre-fabricated parts are quicker and often less expensive but often lose some of the precision and detail that happens with a custom joiner and can come back to haunt an installer or be something less refined.

5. How do you ensure joinery for long life?

Proper maintenance is one key to joinery longevity. Treatment with sealants or varnishes on wooden joinery at regular intervals protect against moisture and wear and tear. For metal joinery, protective coatings resisting rust could also be applied and regular inspections to ensure metals’ structural integrity. MGB Joinery and Building makes use of high quality material combined with precision to minimize the needed repairs and care.

© Copyright 2023 | MGB Joinery Pty Ltd | All Rights Reserved

Web Design By Newy Design Co

© Copyright 2023

MGB Joinery Pty Ltd | All Rights Reserved

Web Design by Newy Design Co